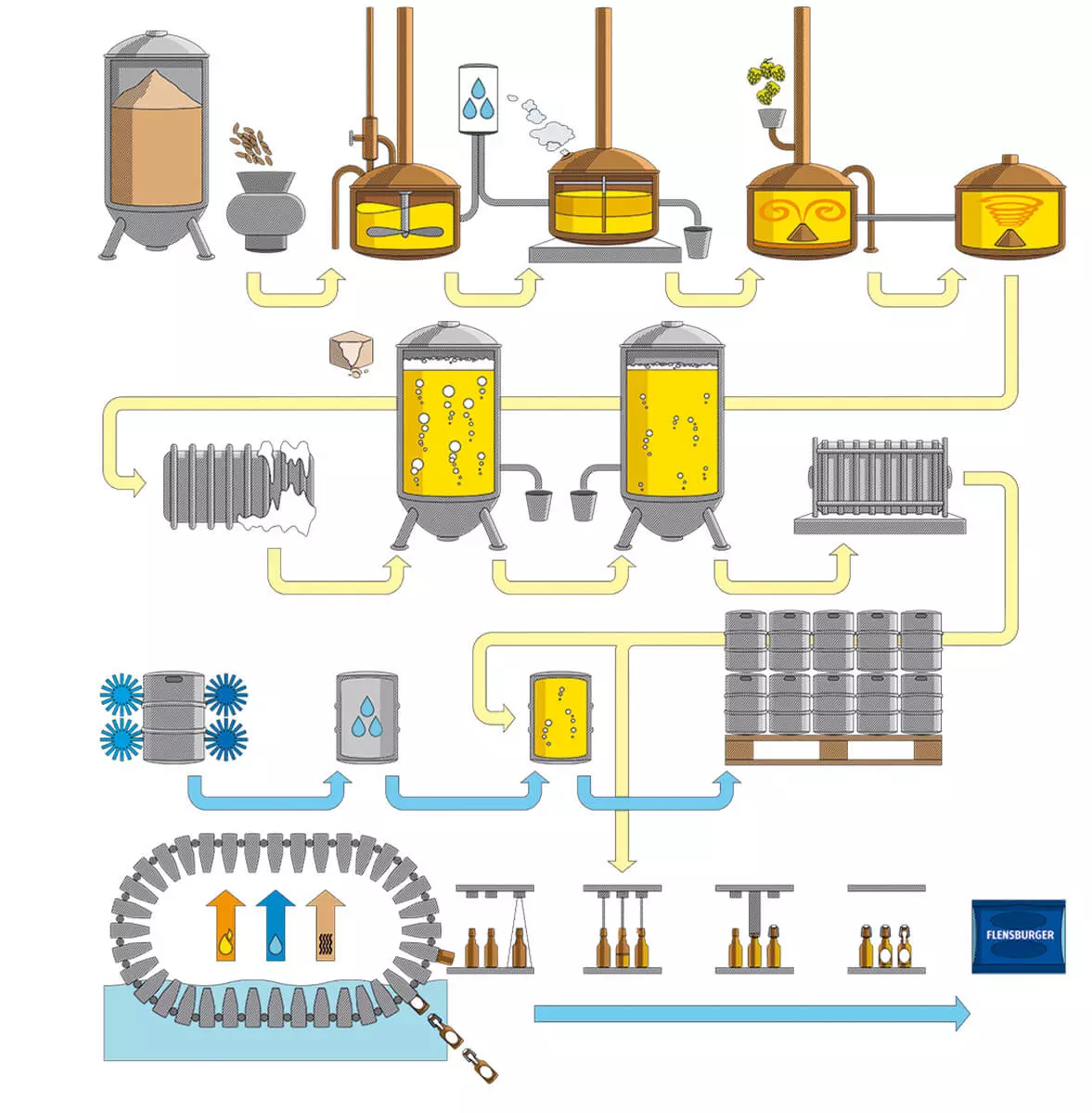

The Brewing Process.

How Does The Brewing Process Work?

Abstract

Straight to the point: we explain the brewing process - including the purity law and ingredients. Don't worry, it won't be boring - after all, it's about beer.

1,2,3,4 - Beer: Four Ingredients Are A Must, But No More Please.

If the beer is to be decent and is brewed in Germany, the German Purity Law is mandatory. In principle, it makes the brewing process very simple, as it states that only four ingredients may be used in beer production: Water, hops, yeast and malt, obtained from barley or wheat. That's all it takes to brew a beer.

For the brewing process in our Flensburg brewery, we use crystal-clear, natural mineral water from the Flensburg glacier spring and malt, which we obtain from coastal barley that grows high up in the north between the seas. Paired with the finest hops from the Hallertau region and yeast from our own yeast breeding facility, we brew our FLENS with a strong character.

As you can imagine, the actual brewing process is much more than just throwing all the ingredients into a brewing kettle and boiling them up - which is why we will now explain the art of brewing to you step by step.

Beer Production From Coastal Barley To Swing-Top Bottles.

Malting.

The first step in beer production is all about the barley. The maltster turns it into brewing malt: For malting, the fresh barley is first soaked in natural mineral water from the Flensburg glacial spring. The soaked barley is then placed in germination boxes and begins to germinate. This releases the necessary enzymes that are essential for the subsequent brewing process.

It is important that our master brewers do not miss the right moment during germination to initiate the drying of the barley. The typical sweetness of malt is created during kilning.

Crushing And Mashing.

Once our coastal barley has become dried malt, our master brewers begin the mashing process. This prepares the malt perfectly for mashing. During mashing, the crushed malt is heated with water in the mash tun and mixed so that the starch can be released from the malt and transformed into malt sugar by the activated enzymes.

Now the processing of barley for beer production is almost complete. The brewing process continues with lautering.

Lautering.

When someone is purified, he or she no longer has any fluff in their head - and so the brewing process is just as much about clarifying. Solid and liquid components are separated from each other in a lauter tun.

The solid components, known as spent grains, are removed and can be used as nutritious animal feed. What remains is a liquid brew: the mash. This is now used in the next stage of beer production.

Wort Boiling With Hops.

Wort boiling gives the beer its typical bitter taste. This is because the mash obtained from the barley is boiled in a wort kettle and refined with hops during this process.

The boiling process releases the bitter substances in the hops. The amount of hops used in the wort boiling process varies depending on whether a more palatable or more bitter beer is to be brewed. In principle, the following applies to the brewing process: the more hops used in beer production, the more bitter the beer.

However, the taste of the beer can be influenced by more than just the quantity of hops used in wort boiling. The type of hops or the timing of the addition of hops is also decisive for the taste of our FLENS.

From Wort Boiling To Original Wort.

Once wort boiling is complete, the wort is allowed to relax in the pool - seriously: the wort is pumped into a cooling vessel, which is often referred to as a whirlpool these days. Rotating movements separate precipitated protein and undecomposed hops from the brew so that a clear wort can be drawn off: the spent wort.

The wort is then filled into a wort cooler and cooled down from 100 degrees to around 10-12 °C. This produces the so-called original wort. This produces the so-called original wort, which is required for fermentation in the next step of beer production.

The Addition Of Yeast And Secondary Fermentation.

As soon as the wort has cooled down to a certain fermentation temperature, our master brewers add our own pure yeast to the wort in the fermentation cellars. This process is called pitching. The yeast now converts the malt sugar into alcohol and carbon dioxide is produced. At this point, the beer is no longer referred to as wort but as green beer.

Once fermentation is complete, the yeast sinks to the bottom of the fermentation tank and can be harvested. The beer is then stored in a storage tank for three to six weeks in the brewing process, depending on the variety, and continues to ferment. During storage, the last yeast residues and precipitated protein seep to the bottom. Beer production is now almost complete.

Filtration In The Brewing Process.

One of the final steps in beer production is filtration. The yeast residues and the precipitated protein as well as hop resins that have seeped to the bottom during secondary fermentation are now filtered. This gives the beer its typical clear color and removes any suspended matter.

Filling Into Our Swing-Top Bottles.

Our beer is now ready - and just needs the right outfit: after the brewing process, it's time for bottling. In our Flensburg brewery, the beer is filtered and then bottled in the typical FLENS swing-top bottles. Stylishly packaged, our FLENS is now ready for retail and the plop'-fresh enjoyment of beer at home and in your favorite pub.

The Brewing Process For Practitioners: The Brewery Tour.

If you find the theory interesting but are more interested in the practice, then a brewery tour in our Flensburg brewery is just the thing for you: Here you can see one or two steps in the brewing process live and with a detailed explanation.

It goes without saying that at the end the beer will be tested to see if it is a success. It's best to register now! By the way: You can order the fan equipment in advance in our Plop Shop or of course buy it on site.